COMPOSITE HIGH POWER ROCKET MATERIALS

MOTOR CASINGS - PHENOLIC

Paper base XX Phenolic tubing - a standard for the manufacture of expendable composite

rocket motors. Simply line with carbon cloth or paper liners and cast the propellant. Sold

by the foot (maximum shipping length is 24"). Note:the 16" lengths are limited

in supply (end cuts) - call for availability or list substitute in the event they are out

of stock.

24mm - .75" ID X .875" OD

24mm - same as above X 16" lengths ( .50")

29mm - 1.00" ID X 1.125" OD

29mm - same as above X 16" lengths ( .50")

38mm - 1.25" ID X 1.50" OD

38mm - same as above X 16" lengths ( .50")

COMPOSITE ROCKET MOTOR TOOLING - CORE BURNING GEOMETRY - PHENOLIC CASINGS

Machined from solid 6061 tool stock aluminum for long life and designed for

use with our phenolic motor casings listed above. Each set contains base, four

propellant coring spindles (two each of two diameters), pulling handle,

centering rings, 10 delay element liners and compression ram and complete

instructions (propellant formulae not included). You can machine your own

nozzles out of graphite, phenolic, fiberglass or Teflon rod stock or they can be

made with our nozzle forming tool sets listed below.

24mm - core burning grain

inquire about availability

29mm - core burning grain

inquire about availability

38mm - core burning grain

inquire about availability

54mm - core burning grain

inquire about availability

CENTERING RING AND BULKHEAD LINERS W/CENTER HOLE - 38mm & 54mm

These are the same as supplied with the composite rocket motor tooling listed above for phenolic cases. These kraft paper discs are used to center the coring spindle while curing and supply a permanent insulation barrier over exposed propellant grain thus constructing the bulkhead barrier. Simply epoxy the delay grain over the core spindle hole formed by the spindle and add chute activation charge. Also used to inhibit the nozzle end propellant grain to reduce surface area of burn, if desired.

SILICONE FLUID (POLYDIMETHYLSILOXANE / PDMS) RELEASE & ANTI-FOAMING AGENT

Used as a mold release agent for casting proprllants, it is first applied to the coring spindle, casting mold, etc.. For stick free removal of cast propellants, plastics, epoxies, etc.. Also effectively eliminates foaming when added to composite propellants. 2 drops per 5 lb batch is all that is required. Large 2 oz bottle goes a long way, enough for hundreds of applications.

Silicone emulsion mold release and anti-foam propellant additive

NOZZLE FORMING TOOL SETS - MOLDED GRAPHITE COMPOSITE ROCKET MOTORS

Machined from high carbon steel and aluminum, these tool sets offer the hobbyist

a means to make high heat & erosion resistant graphite composite nozzles for

use in higher combustion temp composite rocket motors and others. The sets

consist of a heavy wall carbon steel mold sleeve, base with divergence forming

cone and a ram which is completely adjustable according to the degree of erosion

and heat/gas resistance required. You can design and produce nozzles to burn out

slightly for core burning geometries or those that have little or no erosive

loss to retain full pressure during combustion for bates grain and moon burning

geometries, etc. Make 25 to 50 nozzles per hour for as little as $0.15 each!

Using a mixture of powdered graphite and other materials, you simply add a

measured amount of mix to the mold sleeve, compress to a mark on the ram and

eject. The more pressure used, the higher the density and the more erosion

resistant they are. Once you have several, they are cure baked in an oven and

drilled any diameter you need for the proper exhaust vent - fully adjustable for

pressure release! The sets produce nozzle pellets the diameters listed which are

shrink controlled by the oven heat. They are designed to fit the casings listed

for each but can be made to fit casings of similar size as well.

1.010" (FOR 29mm CASE #PHEN29)

1.300" (FOR 38mm CASE #PHEN38)

1.887" (FOR 54mm CASE #PHEN54)

NOZZLE MATERIALS - BLANK ROD STOCKS FOR MACHINING

Due to the wide range of burn durations, power ratings and grain geometries to choose from, we have added a variety of blank nozzle stocks for your custom designs. Listed according to their maximum heat resistance properties starting with the highest (lowest erosion) material - GRAPHITE. For those of you who have computer program designs using particular nozzle materials for specific erosion rates, we list their maximum temp resistance. The actual erosion points will be higher. This information supplies you with alternative erosion factors by choosing other nozzle materials. Sold only in increments of one foot. Note; materials listed with no pricing, we do not carry but list the information for your benefit.

| NSGRA625 |

.625" dia Solid Graphite |

±5000° F (oxidizes) |

|

| NSGRA750 |

0.75" dia Solid Graphite |

±5000° F(oxidizes) |

|

| NSGRA100 |

1.00" dia Solid Graphite |

±5000° F(oxidizes) |

|

| NSGRA125 |

1.25" dia Solid Graphite |

±5000° F(oxidizes) |

|

| |

|

|

|

| ------- |

Silicone Resins |

+450° F |

|

| ------- |

G-7 Fiberglass |

338° F |

|

| ------- |

G-10 Fiberglass |

284° F |

|

| |

|

|

|

| ORDER NSPHE750 |

0.75" dia Phenolic XX |

284° F |

$11.30/ft (6 oz) |

ORDER NSPHE100 |

1.00" dia Phenolic XX |

284° F |

$20.40/ft (8 oz) |

| NSPHE150 |

1.50" dia Phenolic XX |

284° F |

|

| NSPHE200 |

2.00" dia Phenolic XX |

284° F |

|

| |

|

|

|

| ------- |

Nylon 6/12 |

210° F |

|

| ------- |

Acrylic |

180° F |

|

| ------- |

Nylon 6/6 |

170° F |

|

| |

|

|

|

ORDER NSFG625 |

.625" dia Fiberglass |

170° F |

$8.10/ft (6 oz) |

ORDER NSFG750 |

.750" dia Fiberglass |

170° F |

$9.60 (8 oz) |

| NSFG100 |

1.00" dia Fiberglass |

170° F |

|

| NSFG125 |

1.25" dia Fiberglass |

170° F |

|

| NSFG150 |

1.50" dia Fiberglass |

170° F |

|

NOZZLES - MACHINED, UNFINISHED

Cut, faced and machined to form convergence and divergence angles with

pilot hole drilled for throat. You finish drilling/enlarging the pilot hole to form proper

throat diameters as per your motor requirements. Finished nozzles may be used in expendable motors

and by cutting an 'o' ring groove, in reloadable system designs as well.

NO PRICING ON THESE YET

NSM/100FG

1.00" OD X 1.50" LONG -

FIBERGLASS)

NSM/100PH

1.00" OD X 1.50" LONG - PHENOLIC

NSM/150FG

1.50" OD X 2.00" LONG - FIBERGLASS

NSM/150PH

1.50" OD X 2.00" LONG - PHENOLIC

NSM/200PH

2.00" OD X 2.00" LONG - PHENOLIC

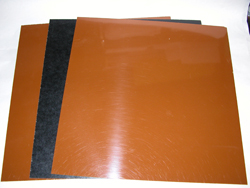

EPDM RUBBER - CHAMBER INSULATION

This thin rubber insulation is applied to the inner wall of the motor chamber to insulate the casing from the combustion heat generated during operation, thus increasing the life of reuseable casings and allowing adequate low cost materials to be used as expendable motors. The propellant may be cast directly into the EPDM lined chambers or an additional liner of carbon cloth be placed between EPDM and propellant thus allowing the higher cost EPDM to be used again. Unused NASA surplus.

EPDM - Carbon Fiber Filled 21.50" wide X .109" thick

EPDM - Textured For Bonding 21.50" wide X .109" thick

EPDM - Textured For Bonding (nat rubber) 21.50" wide X .109" thick

EPDM - Asbestos/Silica Filled 21.50" wide X .109" thick

EPDM - Natural Rubber 21.50" wide X .109" thick

Basic applications; .030" = F through I motors, .101" & .109" = I through K motors, .215" = L and larger

CARBON GRAPHITE CLOTH HEAT SHIELDING - LINER & GASKET MATERIAL

Used by NASA for heat shielding and protection where direct heat, flame or

high heat transfer is a problem. Industrial thermite cannot burn through it!! Flexible cloth-like weave (rayon

fibers) which is graphitized under high pressure, leaving a super thin web (.027" thick) enables its use most anywhere

including fireproof gaskets and casing liners in rocket motors or other devices,

blast plate protection on launch pads or welding applications, firewalls, etc.

Use to line inner casings and cast or compress propellants, smoke comps, etc.

directly into them for protection from burn-through. Lowest cost insurance money

can buy! Easily cut with scissors or punched with disc cutters.Can be "painted" with high heat resisting epoxy or fiberglass resin and sandwiched together in a hot press to form under pressure and heat. Make most any thickness, including blocks for lathe turning into re-useable rocket motor nozzles or nose cones (hollow out for nose cones).

"CLOTH OF A THOUSAND USES"

Graphite Cloth .027" thick X 2.5" wide

Graphite Cloth .027" thick X 3" wide

Graphite Cloth .027" thick X

5" wide

Graphite Cloth .027" thick X

6" wide

Graphite Cloth .027" thick X

6.5" wide

Graphite Cloth .027" thick X

7" wide

Graphite Cloth .027" thick X

7.5" wide

Graphite Cloth .027" thick X

9" wide

Graphite Cloth .027" thick X

10" wide

Graphite Cloth .027" thick X

11" wide

Graphite Cloth .027" thick X

12" wide

Graphite Cloth .027" thick X

42" wide

This length requires an extra shipping carton by itself

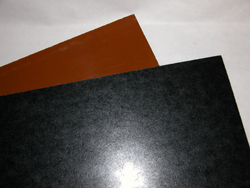

CHAMBER & PROPELLANT LINER STOCK - FIBERGLASS .040"

High tensile strength semi-rigid heat resistant fiberglass sheathing, textured for high strength bonding to various substrates. Can be used as chamber liner in both composite propellant systems and hybrid motors to increase strength and act as a heat sheild between propellant liner and motor casing. Can be used in motor casings of two inch diameters and up by dipping in boiling water to soften before molding into place. Once cool, it retains its shape. Hundreds of crafting applications to make forms for other objects or devices.

Fiberglass Cloth .040" thick X 5.00" wide

Fiberglass Cloth .040" thick X 6.00" wide

Fiberglass Cloth .040" thick X 6.25" wide

Fiberglass Cloth .040" thick X 6.50" wide

Fiberglass Cloth .040" thick X 9.00" wide

Fiberglass Cloth .040" thick X 48.00" wide

This length requires an extra shipping carton by itself